What are the advantages of car headlight tape

Car headlight tape is a special tape used to repair or replace the protective glass of car headlights. It is different from other tapes, it has stronger viscosity and better transparency, with waterproof, anti-ultraviolet, anti-gasoline and other characteristics, so it is widely welcomed. 1. High-strength car lamp tape is made of high-strength material, which can effectively protect the lamp glass from being damaged. Its strength and impact resistance are much higher than other ordinary tapes. 2. High transparency Car headlight tape has high transparency, which can make the light penetration of the headlight unaffected. At the same time, its color is similar to the color of the headlights, which does not affect the aesthetics of the car. 3. Multi-functional vehicle headlight tape also has a variety of functions, such as waterproof, anti-ultraviolet and anti-gasoline, which makes it can be used in a variety of environments. In addition, it can also be used for a long time without problems such as falling off. 4. Easy maintenance For lamp damage, we can use car lamp tape to repair, do not need to replace the whole lamp, which can not only save costs, but also speed up the repair speed. 5. The use of high safety car headlight tape can improve the safety of vehicle driving. It can protect the lamp glass from damage, prevent light leakage and astigmatism, so that the driver can drive more at night likedislike

Jul 19,2023

Why is the car headlight tape so important, the car headlight tape can escort your driving safety

Car headlight tape is a good helper to avoid cracks and scratches caused by friction. So what do you need to pay attention to when using car headlight tape? Fully clean the surface of the lights and try to remove all dust and oil. When pasting the tape, ensure that the edge of the tape is completely fitted to the surface of the lamp to avoid pulling and folding. You can cut it out to size and then stick it on. Don't stick tape on your headlights for more than three months. If the tape is not changed for a long time, the surface of the headlights may be corroded due to the chemical composition of the tape. Be careful and gentle when applying the tape. Pulling too much tape too hard or at once can cause the tape to break or leave paint and scratches. The tape on the rearview mirror is pointed, and it must be affixed in the direction of the arrow, otherwise it may cause the tape to fall off during friction or the tape may block the field of view of the rearview mirror and affect the driving safety. Automotive headlight tape is generally composed of polyester film and anti-fouling coating. Its main role has the following points: to protect the surface of the lamp from the influence of friction, to avoid the occurrence of lamp deformation, cracks, scratches and so on. Improve the recognition and brightness of the headlights, so that the headlights shine farther and brighter. Keep your lights clean and bright, free from dust and rain. Because the essence of the headlight tape is a kind of anti-fouling coating, it can make the stain not

Jul 31,2023

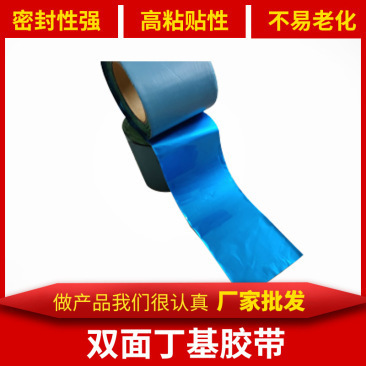

How to choose butyl hot melt sealing tape suitable for manufacturing

Butyl hot melt sealing tape is an important material widely used in manufacturing industry. It has excellent sealing performance and high temperature resistance, and is widely used in packaging, construction and automotive fields. However, in many butyl hot melt sealing tape products, how to choose the tape suitable for manufacturing has become an important problem. This article will show you how to choose butyl hot melt sealing tape suitable for manufacturing, and provide you with some useful advice. First of all, the selection of butyl hot melt sealing tape suitable for manufacturing needs to consider its high temperature resistance. In manufacturing, high-temperature environments are very common. Therefore, the selection of high temperature resistant butyl hot melt sealing tape is very important. This tape should be able to maintain its adhesive properties in a high temperature environment without deformation or loss of viscosity due to high temperatures. Secondly, the sealing performance is also one of the important considerations in the selection of butyl hot melt sealing tape. In the manufacturing industry, sealing performance directly affects the quality and safety of products. Therefore, the selection of butyl hot melt sealing tape with good sealing performance can ensure the quality and performance of the product. This tape should be able to effectively prevent the intrusion of external substances such as liquids, gases and dust. In addition, the choice of butyl hot melt sealing tape suitable for the manufacturing industry also needs to consider its corrosion resistance. In some

Aug 09,2023

Rubber sealing material is indispensable in the manufacturing industry

Indispensable rubber sealing materials in the manufacturing industry, rubber sealing materials play a vital role. The properties of this material make it indispensable in many applications. In this paper, butyl hot melt sealing tape, a kind of rubber sealing material widely used in manufacturing industry, is introduced, and its importance and application in manufacturing industry are discussed. Butyl hot melt sealing tape is a kind of rubber sealing material with excellent weather resistance and chemical stability. It is made of high quality butyl rubber with good elasticity and adhesion properties. This tape is widely used in the manufacturing industry in the fields of sealing, insulation and protection, providing important support and guarantee for the manufacturing process. First of all, butyl hot melt sealing tape plays an excellent sealing role in the manufacturing industry. It can effectively prevent the penetration of liquids, gases and impurities, ensuring the stability and reliability of the manufacturing process. Whether in the process of automobile manufacturing, aerospace engineering or electronic equipment manufacturing, butyl hot melt sealing tape is widely used in various sealing interfaces, effectively preventing leakage and pollution. Secondly, the insulation function of butyl hot melt sealing tape in the manufacturing industry is also indispensable. It has good electrical resistance and heat resistance, can effectively isolate current and heat, and protect

Aug 19,2023

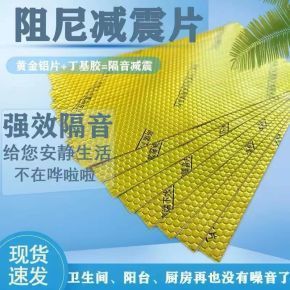

Development and application of new type rubber water stop belt

In recent years, with the continuous development of construction technology, butyl waterproof sealing tape as a new type of rubber water stop has gradually attracted people's attention. It has excellent waterproof and sealing performance, and can be widely used in the basement, pool, bathroom and other places in the construction project. This paper will discuss the development and application of butyl waterproof sealing tape, and in-depth understanding of its importance in the construction industry. First of all, let's understand the characteristics of butyl waterproof sealing tape. Butyl waterproof sealing tape is a rubber water stop belt made of high-performance butyl rubber material. It has good weather resistance, aging resistance and chemical corrosion resistance, and can maintain a stable sealing effect under different temperatures and humidity. In addition, butyl waterproof sealing tape also has good flexibility and adhesion, can adapt to the deformation and vibration of the building structure, to ensure long-term waterproof effect. Secondly, butyl waterproof sealing tape is widely used in construction projects. First of all, it can be applied to the waterproofing of the basement. Basements are usually located at a high water table and are vulnerable to groundwater immersion and infiltration. The butyl waterproof sealing tape can effectively prevent the penetration of moisture and ensure the dryness and safety of the basement. Second, butyl waterproof sealing tape also

Sep 19,2023

The butyl waterproof sealing tape necessary in the wind power industry

In the wind power industry, butyl waterproof sealing tape is an indispensable material. It is widely used in key components of wind turbines, such as towers, nacelles and blades. Butyl waterproof sealing tape has excellent waterproof performance and durability, and can effectively protect wind power equipment from moisture and other external factors. This paper will introduce the characteristics of butyl waterproof sealing tape and its important role in wind power industry. First of all, butyl waterproof sealing tape has excellent waterproof performance. In wind turbines, the equipment is exposed to the outdoor environment and is vulnerable to erosion from rain, moisture and Marine salt spray. Butyl waterproof sealing tape can effectively seal the seams and gaps of the equipment, preventing water penetration, thereby protecting the equipment from corrosion and damage. Its good waterproof performance can extend the service life of the equipment and reduce maintenance and replacement costs. Secondly, butyl waterproof sealing tape has excellent durability. Wind turbines usually need to operate in harsh climatic conditions, such as strong winds, extreme cold and high temperatures. Butyl waterproof sealing tape can withstand the challenges of these extreme environments and maintain its excellent performance. It has good weather resistance and aging resistance, and can maintain its elasticity and adhesion for a long time to ensure that the sealing effect of the equipment is durable and reliable. this

Sep 13,2023

How to choose butyl waterproof sealing tape suitable for steel structure

How to choose butyl waterproof sealing tape suitable for steel structure With the wide application of steel structure in the construction field, the waterproof sealing of steel structure has become particularly important. Butyl waterproof sealing tape, as a commonly used sealing material, has excellent waterproof performance and bonding performance. However, the choice of butyl waterproof sealing tape suitable for steel structure is not an easy thing. This article will introduce how to choose butyl waterproof sealing tape suitable for steel structure, to help readers better understand the product. First of all, the purchase of butyl waterproof sealing tape should consider its applicable environment. Different environments have different requirements for butyl waterproof sealing tapes. If it is an indoor environment, you can choose the general butyl waterproof sealing tape; If it is an outdoor environment, it is recommended to choose butyl waterproof sealing tape with weather resistance and anti-aging properties. In addition, if it is a special environment, such as high temperature, low temperature, acid and alkali environment, you need to choose the corresponding special material made of butyl waterproof sealing tape. Secondly, the bonding performance of butyl waterproof sealing tape should be considered. The sealing requirements of the steel structure are high, and the butyl waterproof sealing tape is required to be firmly bonded on the surface of the steel structure to ensure the sealing effect. Therefore, when selecting butyl waterproof sealing tape, it is necessary to pay attention to its bonding strength and bonding time. May choose to have

Sep 07,2023

Development and development skills of rubber sealing materials

Rubber sealing materials are widely used in various industries, including butyl hot melt sealing tape as a common sealing material, with high heat resistance and corrosion resistance. This paper will discuss the development and development of butyl hot melt sealing tape, and its advantages in practical application. First of all, for the development of butyl hot melt sealing tape, the choice of raw materials is crucial. When selecting rubber materials, it is necessary to consider its heat resistance and corrosion resistance to ensure that the sealing tape can maintain stable performance in high temperature and corrosive environments. In addition, it is also necessary to choose the appropriate additives to improve the adhesion and sealing performance of the tape. Secondly, development skills also play an important role in the quality and performance of butyl hot melt sealing tape. Proper process control is needed in the development process to ensure that the thickness and width of the tape meet the requirements. At the same time, reasonable hot melt adhesive formula and the selection of appropriate process parameters are also the key to ensure the performance of the tape. Through continuous testing and improvement, the performance of the sealing tape can be optimized and its ability to adapt to different environments can be improved. Butyl hot melt sealing tape has good resistance to high temperature and corrosion, and is widely used in practical applications. It can be used to seal pipes, storage tanks and other equipment

Aug 29,2023

More information